State-of-the-Art

Avarint provides fully independent third-party testing using live chemical agents and other hazardous chemicals for our customers.

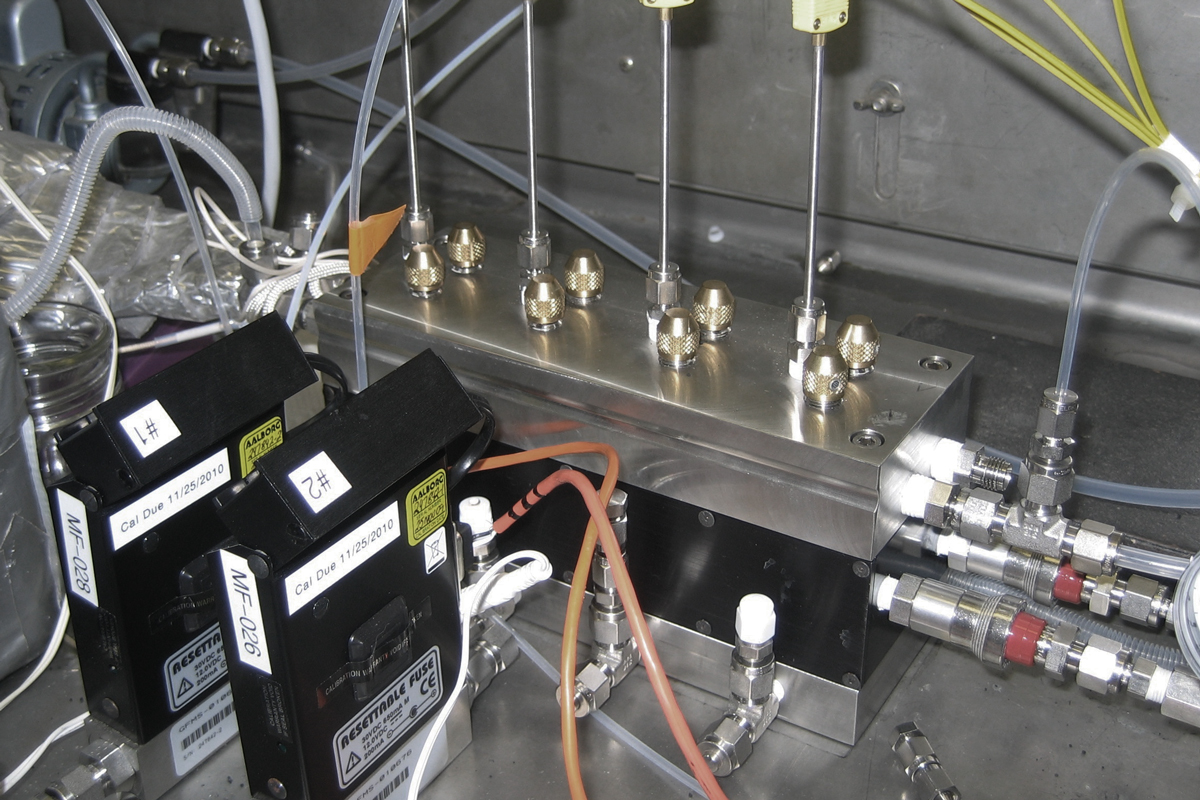

The Avarint facilities are focused on performing live agent testing of detection systems, decontamination technologies, and individual and collective protective equipment against live chemical agent challenges, simulants, toxic industrial chemicals and advanced chemical threats.

Staffed with research scientists and engineers with decades of experience in chemical defense laboratory operations, the facility has been in continuous operation since 1983. Avarint provides its services directly to the Government and Prime Contractors who are designing, developing, testing, manufacturing and selling defensive equipment to the Government.

Capability Highlights

Research & Development

Partner with companies developing early-stage technologies to address challenges posed by chemical threats. We apply our expertise to develop customized approaches to meet the specific testing needs of a program.

Production Lot Testing

Provide testing and data packages to manufacturers of chemical defense products including detector papers, decontamination kits and protective clothing products.

DoD Test Methods

Perform many CBRN-related Test Operating Procedures (TOPs) to support the development of defensive technologies against chemical and biological threat agents.

NFPA Method 1990

Provide chemical agent testing to National Fire Protection Association standards for First Responder protective suits for manufacturers and certification bodies.

Paints & Coatings

Conduct testing and certification of CARC technologies and other specialized surface treatments in accordance with approved methods.

Why Avarint?

Independent organization that does not develop or sell products

Customers receive unbiased performance validation of their products and technologies.

Adept at developing rigorous technical approaches to complex test and evaluation (T&E) problems

Customers receive cost-effective answers to fundamental questions.

Experience with non-standard, complex and large-scale T&E

Data generated has maximum operational relevance at the scale of testing.

Expertise in developing comprehensive documentation packages (test plans, SOPs, technical reports)

Customers receive rapid approval by program T&E leads and T&E stakeholder groups.

ISO 9001:2015 Quality Management System

Accurate, reproducible and defendable data sets and results are provided to customers.